approach

DeepForm’s technology is built on innovation that delivers measurable, real-world impact

Our patented fold-flow process redefines how metal parts are pressed—using a data-led understanding of material behaviour, advanced simulation, and tool design principles developed through rigorous research. The result is a smarter, more efficient alternative to conventional forming that reduces waste, cuts CO₂, and integrates seamlessly into existing production systems.

Beyond the core process, our approach is engineered for scale. Every element – from modelling and validation to tooling and production trials – is designed to work reliably at high volume and across multiple sectors. DeepForm combines scientific insight with practical engineering to create a technology platform that is optimised, scalable, and ready for the future of manufacturing.

TECHNOLOGY

Key advantages

Collaborations

DeepForm CEO Chris Cleaver participated in the prestigious RAEng Enterprise Fellowship programme in 2022-2023

JLR-led £11M consortium to accelerate the development of ultra-resource-efficient vehicle structures for the next generation of electric vehicles.

DeepForm participated in the APC Technology Developer Accelerator Programme Wave 8 in 2024-2025

patents

Patent

Core technology

- Exclusively Licensed to Deepform by Cambridge Enterprise

- W02020043832A1

- Filing date (PCT): 2019

- Status: Granted EU, CN, USA

FIG. 2D

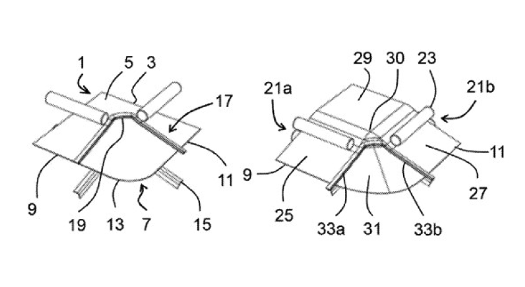

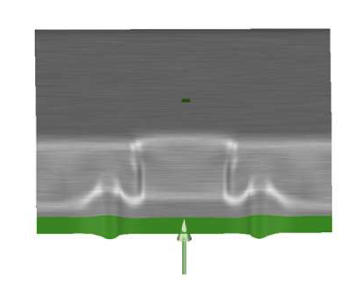

Patent 1 is exclusively Licensed to DeepForm by Cambridge Enterprise, and is the base patent protecting the folding-shearing concept, and which overlaps with each of Patents 2-8.

It protects the concept of folding regions of the part, collecting material in a ‘beak-shape’, and subsequently shearing this material to create the required part.

Patent

Press tool implentation

- Exclusively Licensed to Deepform by Cambridge Enterprise

- W02024079349A1

- Filing date (PCT): 2023

- Status: Granted UK, PCT applications in 7 territories

FIG. 2D

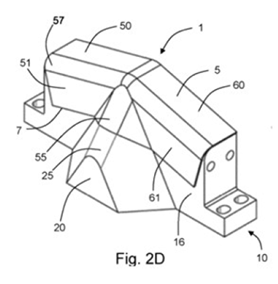

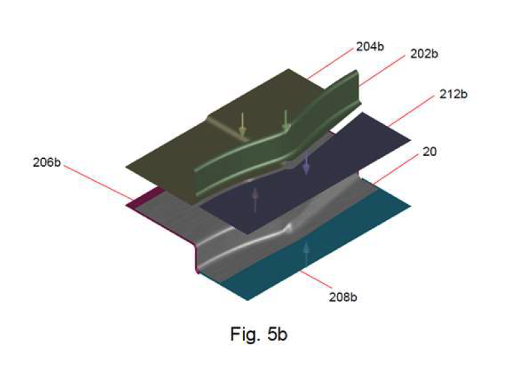

Covers the innnovative steps to implement the ‘folding-shearing’ concept in a press tool.

Patent

Sideplate to control wrinkling

- DeepForm owned

- PCT/EP2024/077169

- Filing date (GB): 2024

- Status: Pending

FIG. 2D

Patent 3 expands the applicability of patent 2 by introducing sideplates that control for wrinkling and is full DeepForm owned.

Patent

Forming parts with flanges (unfolding)

- Exclusively Licensed to Deepform by Cambridge Enterprise

- GB 2417682.8

- Filing date (GB): 2024

- Status: Pending

FIG. 2D

Protects a technique for creating parts with flanges by partially completing the shear operation and ‘unfolding’.

Patent

Thickening control beak design

- Exclusively Licensed to Deepform by Cambridge Enterprise

- GB 2417680.2

- Filing date (GB): 2024

- Status: Pending

FIG. 2D

Covers modifications to the shape of the ‘beak’ which enable better control of the thickening, creating a better product/enabling sharper features to be formed.

Patent

Forming parts with flanges (outer pad)

- DeepForm owned

- GB 2507151.5

- Filing date (GB): 2025

- Status: Pending

FIG. 2D

Covers technology to form parts with flanges in a subsequent operation – key to enabling exploitation on many automative (car and truck) parts.

Patent

Forming stretch corners

- DeepForm owned

- GB 2507149.9

- Filing date (GB): 2025

- Status: Pending

FIG. 2D

Covers using a ‘horizontally’ oriented beak to enable ‘stretch’ features to be made. Material is redistributed by the beak, avoiding excessive thinning or ultimately splitting.

Patent

Forming large radii/round parts

- Exclusively Licensed to Deepform by Cambridge Enterprise

- GB 2511829.0

- Filing date (GB): 2025

- Status: Pending

FIG. 2D

Will cover production of parts with long radii or curves as seen from above, and will have applications beyond automative inclluding beverage cans. The approach has been tested in physical trials at the University of Cambridge.