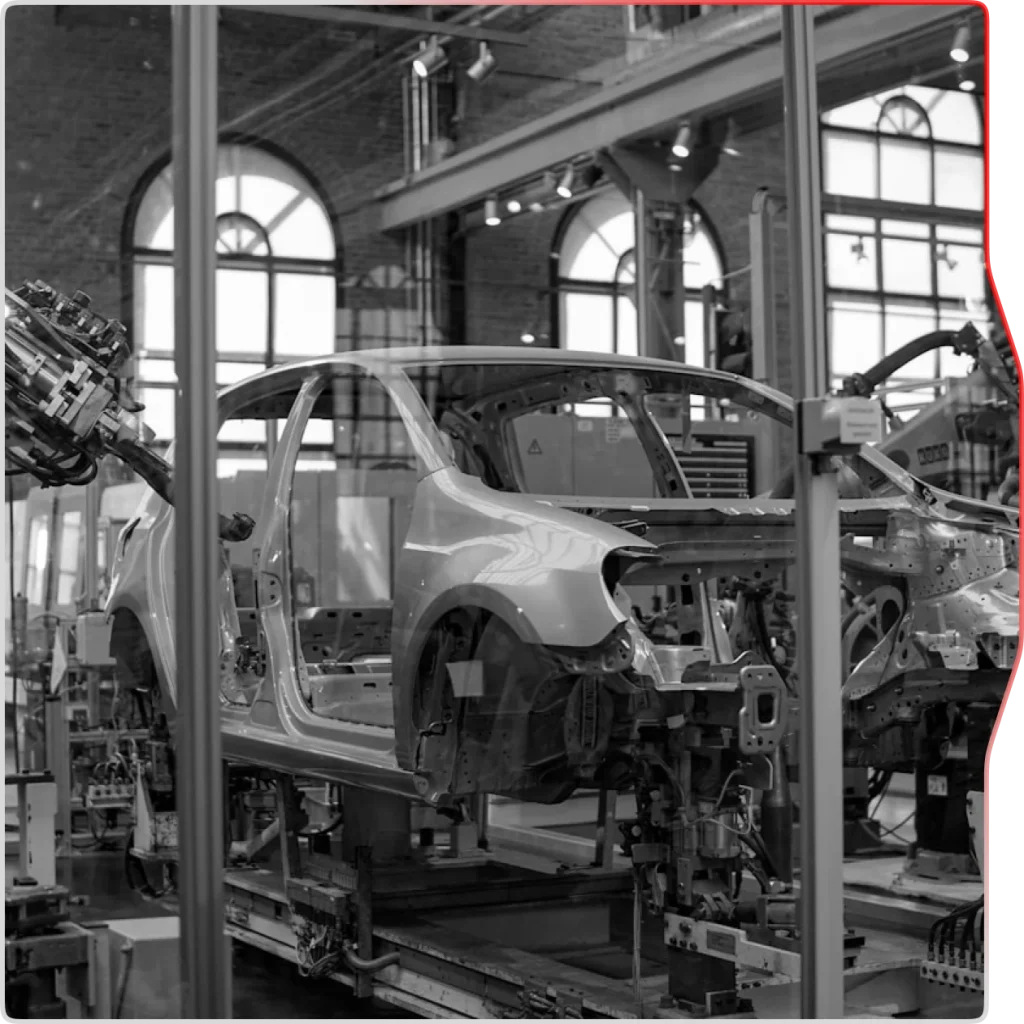

Auto OEMs

As an OEM, facing increasing demand to minimise material waste and emissions while navigating tight margins and stringent government regulations, is standard practice.

Vehicle programs must prioritise engineering validation while also integrating purchasing and sustainability metrics. Key challenges arise in areas such as cost-per-part, material utilisation, and carbon footprint, which require innovative solutions to meet both compliance and market expectations.

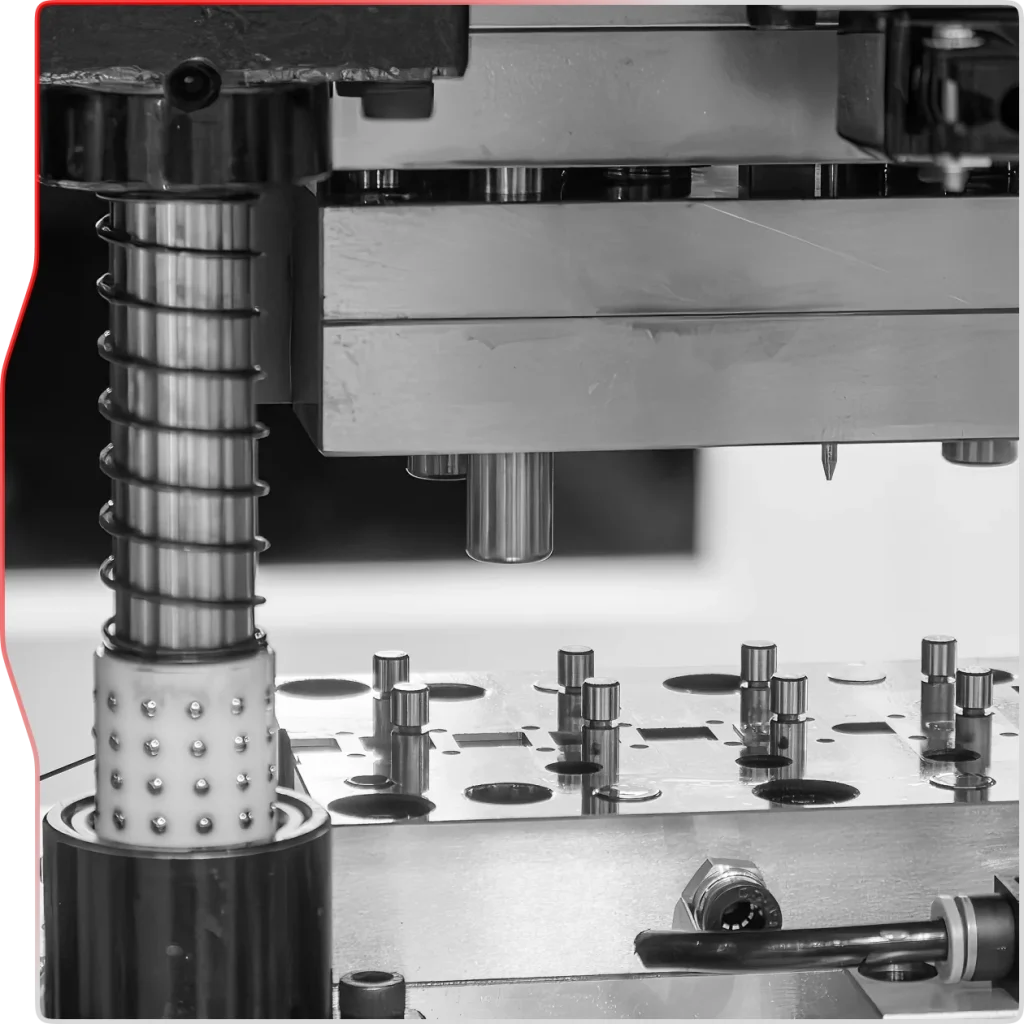

Stampers

DeepForm helps stampers cut material waste, lower part costs, and improve sustainability without changing their existing production lines.

Its patented fold-flow process boosts material utilisation, maintains full-speed output, and enhances forming control—allowing OEM suppliers to deliver higher-quality parts more efficiently and competitively.

beverage can manufacturers

The beverage can industry produces over 300 billion units annually.

Yet 15–17% is lost as blanking and trimming —costing around £630k per 100 million cans and generating high emissions. By improving material utilisation and forming efficiency, DeepForm can help reduce embodied carbon and support a more sustainable, high-volume packaging industry.

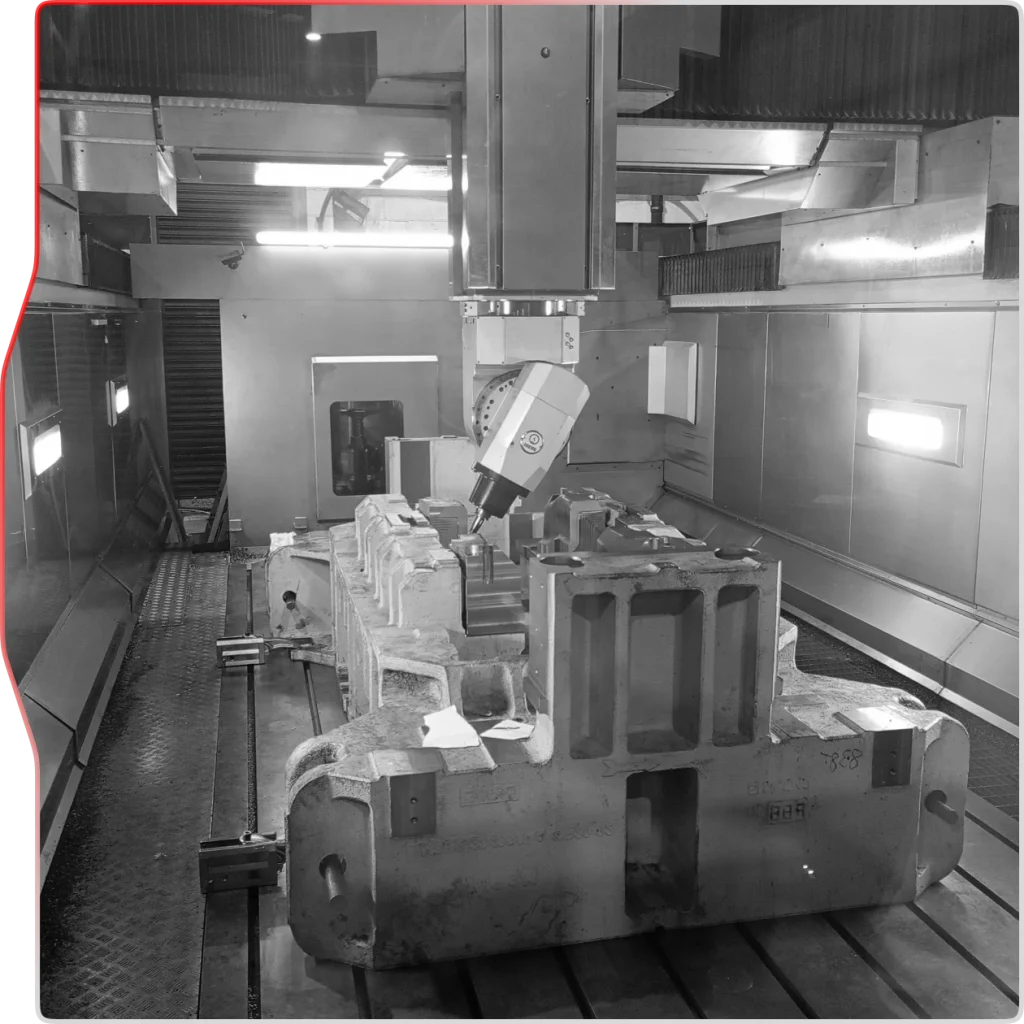

toolmakers

DeepForm gives toolmakers a new competitive edge by enabling tools that deliver higher material utilisation, reduced trimming, and better forming control.

Its fold-flow process integrates into familiar tooling architectures, allowing toolmakers to offer OEMs measurable cost, quality, and sustainability gains while differentiating their tooling solutions with a proven, next-generation process.

“We’re tackling one of the biggest hidden challenges in manufacturing – the amount of metal that ends up as waste.”

Chris cleaver, ceo